As the ninth largest manufacturing nation in the world employing 2.7 million people, UK manufacturing contributes 11% of GVA (Gross Value Added).

As the long-term effects of COVID-19 continue to impact global manufacturing, it’s no surprise that some UK manufacturers are noticing an increase in business.

A survey carried out by Make It British revealed that 50% of UK fashion and textile manufacturers reported an increase in new business since the pandemic. This is proof that UK manufacturers can plug any gaps in the wider supply chain and offer a quicker turnaround during these times of uncertainty.

Quality control & speed

UK manufacturers have the ability to create a product specification which has been tailored to each individual client, giving them the confidence that they will receive a bespoke product – rather than a specification of an imported product which might not be exactly what they require.

With less distance to travel, the time between production and delivery is significantly reduced – no matter the product type. A shorter distance also means an increase in product quality, as there is less chance of products getting damaged in transit.

As everything is on site, it’s easier for UK manufacturers to monitor business practices such as stock audits. It’s also quicker and easier to build rapports with local companies if they need to place an order for faulty parts, for example. Customers will appreciate this quicker, better quality service which could result in repeat business as trust continues to build.

Better for the environment

Every sector – not just manufacturing – is attempting to meet sustainability targets in line with the government’s 25-year plan to improve the environment. UK manufacturing significantly decreases the mileage a product has to travel and in turn, the fuel required. Keeping all work on British soil dramatically lowers a business’s carbon footprint and therefore the damage caused to the environment as a result.

Unrivalled customer care

As well as being able to tailor their services to every client, UK manufacturers can offer more production transparency – even allowing customers to visit the premises and view the production process first-hand.

Both Brexit and COVID-19 have undoubtedly had an effect on global supply chains and the sourcing of raw materials and parts, largely due to travel restrictions. Because of this, local companies are a much more attractive option as they are in a better position to work with smaller minimum order quantities and take advantage of potential relationships with local suppliers.

Supporting the local economy

While there will always be certain benefits associated with offshore manufacturing, there’s never been a better time to ‘keep it local’ and support our own economy. Encouraging British manufacturing creates new job opportunities in local areas, with possibilities for providing tangible skills to future generations.

Not only does UK manufacturing benefit your company directly, but it also impacts the national and local economy and the scale of UK manufacturing itself. With that being said, the ongoing surge in demand for UK manufactured products has the ability to increase your business’s appeal to potential customers.

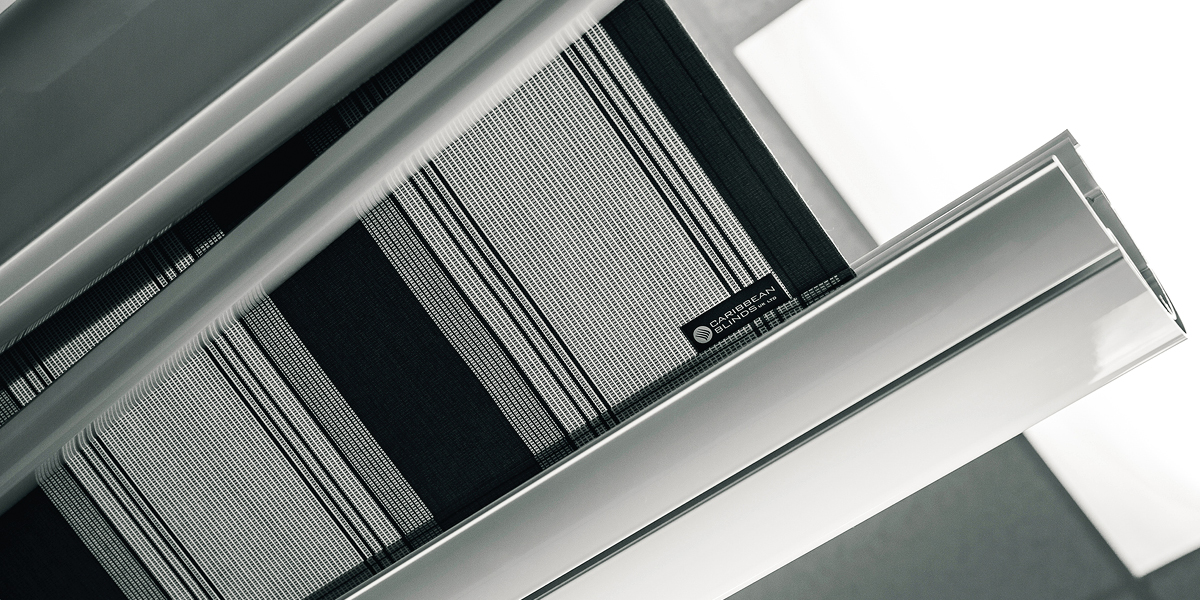

At Caribbean Blinds we’re proud to manufacture our luxury external shading systems right here in the UK and have done since the company’s inception in 1987. From our state-of-the-art production facility in Sudbury, Suffolk, we have the capacity to produce in excess of 10,000 external blinds and awnings every year and hold high stock levels, to ensure we can offer the shortest lead times, which is particularly important at the peak of the season when there is increased demand as soon as the sun comes out! To find out more about our company and see a video of our production in action view our UK manufacturing page here.